DPF Cleaning Machine

Introducing the FH series cleaning machines, exclusively brought to you by FH Solution, a distinguished manufacturer of DPF Cleaning machines based in Switzerland with a global presence. As the sole assembler and distributor for FH Solution in India, DPFXPERT proudly presents the FH series machines to cater to the diverse needs of our customers.Specially curated for the Indian market, our machines are designed to address the unique challenges posed by different sizes of DPFs, SCRs, DOCs, and their combinations and permutations.

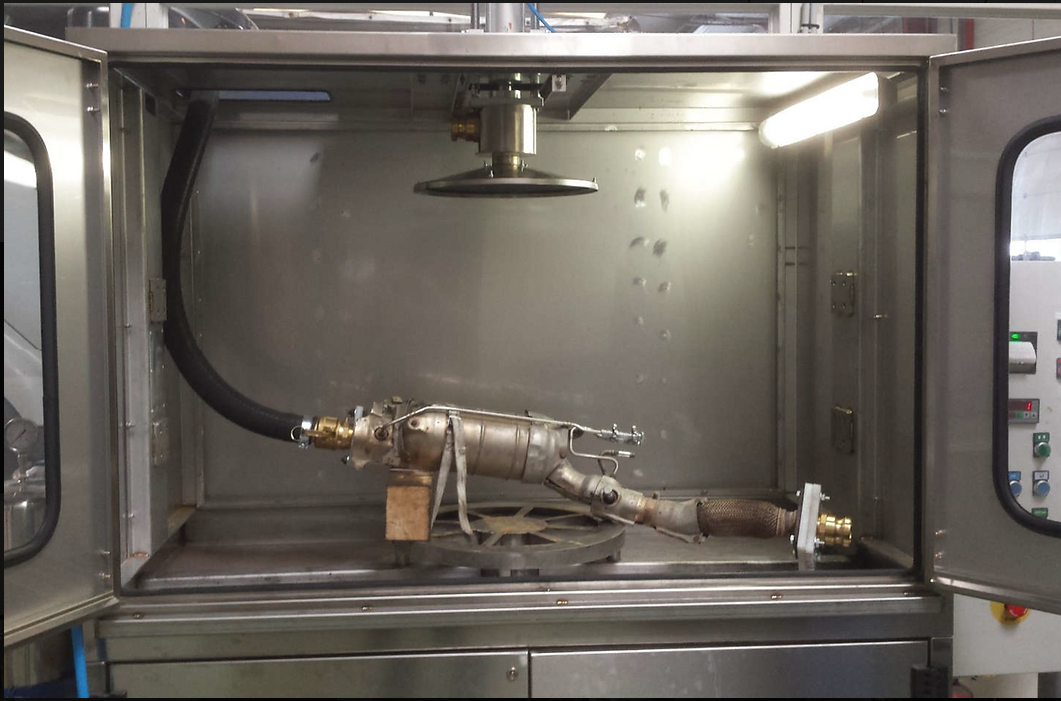

Our FH series machines are meticulously engineered to efficiently clean all types of particulate filters, ranging from cars to vans, light, medium, and heavy trucks, buses, and off-road equipment equipped with a diesel particulate filter (DPF).

With FH Solution’s expertise and innovation, our FH series machines excel in removing PM-10 (soot and ash) from the filter, restoring DPF to an impressive 98% of its original condition. We understand the complexity of diesel particulate filters, especially those in cars, light-medium-sized trucks, which are often sealed and challenging to clean. However, our FH series machines are designed to tackle these challenges effortlessly.

Our machines ensure thorough cleaning of any make and configuration of diesel particulate filter without the need for cutting, modifying, or welding the DPF. Simply connect the appropriate adapter and let our machines do the rest.

During the cleaning process, our machines meticulously test the back pressure within the DPF filter. They then pump high-pressure water mixed with Hydro Carbon fluid at an impressive rate of 160 liters per minute from a dedicated pump. This thorough cleaning process is complemented by blasts of air at 2-3 bar to ensure complete removal of soot and ash from the DPF filter. To guarantee the DPF filter’s cleanliness, the filter is rotated in both directions.

Trust FH Solution’s FH series cleaning machines, assembled and distributed exclusively by DPFXPERT in India, to deliver unmatched performance, ensuring your DPFs are cleaned with precision and efficiency, without compromise. Experience the difference today.

Advanced fast DPF cleaning Process

Compact Design - cleaning efficiently consistently at 98.5%

Cleans virtually any DPF without cutting/welding

Low cost maintenance - Environment friendly

Quality Technical support

All POS Material provided

Full training & support

Training at the DPFXPERT

All the tools, adapters, fluid, clamps and filters needed for 250 DPF cleans

Dedicated geographical area of typically 250,000+ population

Exclusive DPFXPERT map entry

DPFXPERT job reports database

Helps developing the local garage network

DPFXPERT:

Customized solution for your DPF Needs

FH SERIES CLEANING SYSTEM

In these instances the DPF must be cut open, cleaned and welded back together again to restore the filter to serviceable standards or simply replace the DPF costing thousands of dollars.

The FH effectively cleans any make and configuration of diesel particulate filter without cutting, modifying or welding by simply connecting the appropriate fitting.

The FH process outperforms conventional DPF Cleaning technology both economically and in cleaning efficiency because the FH does not utilize pneumatic and/or thermal regeneration technology to remove soot and ash.

There is no need for large volume air compressors, air dryers and expensive electrical service upgrades and the entire

FH System occupies only a fraction of the floor space when compared to other technologies.

Advantages of the Machine

Quicker DPF cleaning process, this reduces costly downtime allowing you to get your customer back on the road.

Flow test before and after in m3/h

30 – 45 minutes for cars and light trucks

60 – 75 minutes for heavy trucks, buses and off road equipment

Cleans virtually any diesel particulate filter without the need for cutting, modification and/welding.

Two high powered water pumps, one dedicated for cleaning and one for circulating the water.

- Cleaning efficiency consistently at 98.5%.

High wattage heating element for faster drying

Has the ability to wash one filter and dry another at the same time

Two self-contained water tanks so all water is recycled (environmentally friendly, no waste)

No particulate matter emissions (dust) or hazardous fumes in the workplace atmosphere making a safer, cleaner work environment.

Compact design occupies a small place (2m2) of valuable floor space.

Requires very little routine maintenance.

A Glimpse into DPF clogging

Diesel Particulate Filters are made of a porous ceramic honeycomb of alternate end closed channels. The exhaust gas enters the DPF and passes through the porous walls of these channels and traps the particulate matter.

Particulate matter (or PM) in the DPF is made up of soot and ash. Soot is normally removed from the DPF through regeneration, but leaving the ash behind in the channels.

In some cases, ash bridging may also occur causing blockages to form near the middle of the filter, effectively blocking flow through the remainder of the channel.

Ash, by definition is incombustible and must be removed from the DPF through an effective cleaning process.

Ash build-up is the primary reason for premature DPF failure and is the most important factor controlling the service life of the filter.

- Ash and soot accumulation restricts exhaust flow, therefore increasing back pressure, making it harder for the engine to breathe. This can greatly affect performance and fuel consumption.

- When the filter is blocked, options such as forced regeneration or chemical additives will only remove some of the soot, but not the ash.

- If high ash levels remain, this will, at best, only be a short-term solution and therefore a potential waste of time and money.

- DPF’s can be restored to virtually new condition by thorough cleaning, removing both soot and ash, as well as recovering DPF’s with oil and coolant contamination.